Hi all...new to the forum. Looks like I will learn alot here.

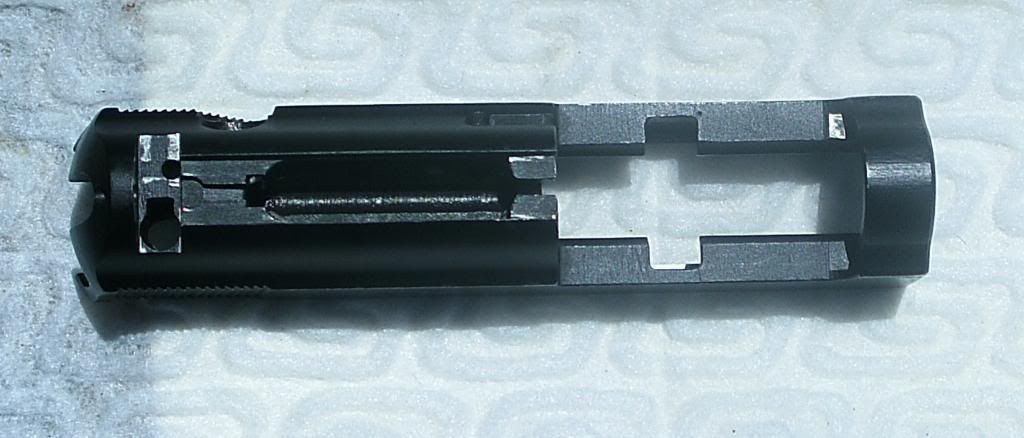

I have a 1960 P-1 that much to my dismay now has a 1/4" crack on the slide.

My question is I have seen some "new" P-1 stripped slides

on Ebay today with no serial no. for a good price. Would

there be a problem with these fitting my 1960 P-1? Any fitting

issues? Thanks for any help.

Since found out that the slide on ebay is an 82 manufacture.

But why no serial no.?

..

Moderator Edit: Photos copied from end of thread:

.

![Image]()

.

![Image]()

.

![Image]()

I have a 1960 P-1 that much to my dismay now has a 1/4" crack on the slide.

My question is I have seen some "new" P-1 stripped slides

on Ebay today with no serial no. for a good price. Would

there be a problem with these fitting my 1960 P-1? Any fitting

issues? Thanks for any help.

Since found out that the slide on ebay is an 82 manufacture.

But why no serial no.?

..

Moderator Edit: Photos copied from end of thread:

.

.

.