No problem, 'Pppr. I know how you feel; when I first came around here I didn't have a camera either. Whenever you get around to it, but I understand the situation better now because of your more-detailed description above.

Let's get a little nerdy here and better understand the points of force at play when the P.38 is fired. I just got mine out of the safe and I'll try to illustrate what

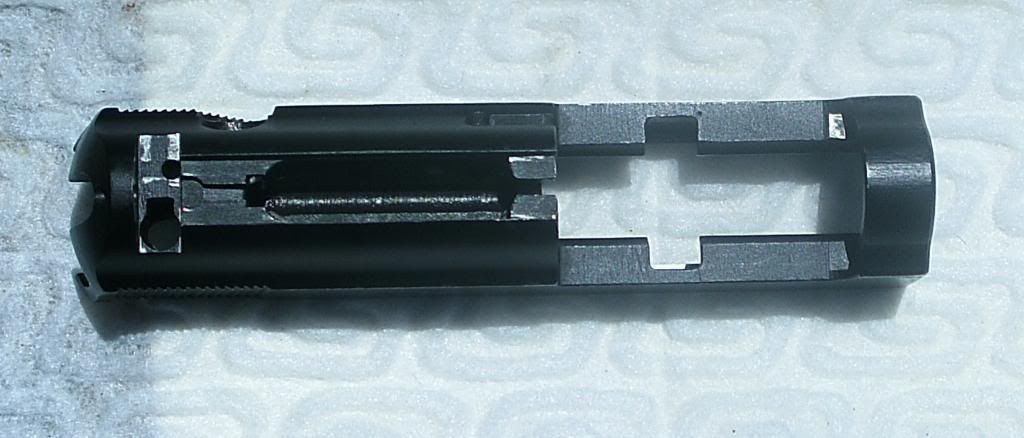

Mike described in #29 and the physics at play as far as the interaction between the slide and barrel assembly is concerned. When the P.38 is fired, the immediate force is applied directly to the breech face of the slide by the base of the cartridge, followed immediately thereafter by the barrel assembly. As the bullet is forced down the barrel by the propellant gasses, an immediate opposite reaction is applied and forces the barrel in the direction depicted by the red arrow.

At this point, the barrel and slide are locked together by the ears of the locking block and their interaction with the corresponding cutouts in the slide. They travel rearward together approximately 10 mm before the button at the face of the locking block is depressed upon reaching the block in frame, which then lowers the ears and unlocks the barrel from the slide:

The full force of this reaction is applied to the cutouts in the slide in the direction of the red arrows. All of the mass of the slide must now follow this direction until it reaches its mechanical stop at the rear of the frame, and the force is applied as detailed.

This normally would not be an issue were it not for the fact that the slide of the P.38 has a quite a bit of mass located

behind this point of force. This mass must be

pulled by the rearward-travelling slide, as detailed in blue and creates a potential stress point in the slide where the forces interact.

As discussed earlier, my P.38 has had

many thousand bullets down the barrel since I bought it a few years ago, and it was like brand new when I got it. It's still quite pristine and shows zero damage to the slide, frame, or mechanical contact points. I have fired mostly WWB 115 grain range ball, some Magtech, PPU, PMC, and even some of the Russian junk (very little - less than a few magazines worth). I have also fired just about every commonly available personal defensive cartridge as well. Critical Defense, Hydra-Shok, PDX1 etc but never anything silly. If I see a "+"

anything on a box on ammunition on the shelf, I pass it by. As you can see, there is no visible wear to the slide of my P.38 at the stress points.

I have a feeling I'm going to be an old man, crusty and grumbly like Mike, before I have to worry about the slide breaking in my P.38. Of course, there is no

visible wear to my slide thus far. Visible... what of the crystalline structure of the metal along that stress line? These are things that cannot be seen, and where good metallurgy comes into play. Like any other mechanical device that experiences repetitive flexing, impact and heating/cooling stresses, wear will eventually occur and

could lead to failure over a long period of time. I could also win a million dollars, and I could also get struck by a meteorite as well as my slide breaking.

The moral of the story: If you have a vintage P.38 with a "thin" slide like mine, unpinned frame, or are otherwise fearful don't place unnecessarily overpowered ammunition or "hot" handloads into the magazine. Rather, insert economical range ball instead, quit fussing, and enjoy your Walther!

-Pilotsteve

![Image]()

![Image]()

![Image]()